2006 Kokusai Electric Co., Ltd Quixace II Doped Poly

2006 Kokusai Electric Co., Ltd Quixace II Doped Poly

Contact us for price

Available quantity:2

Description

Vintage: 2006

Wafer size: 300mm

Process: POLY

From original tool PO, please inspect to verify

3-1 Furnace Unit

1. Cartridge Heater D4EX28804 1

2. T/C for Heater Control D4EX24431 5

3. T/C for Over temperature Protection D4EX15442 5

4. L type T/C for Cascade Control D4EX26037 1

5. 5Point T/C for Profile Control D4EX26038 1 OPTION

6. 1Point T/C for Profile Control D4EX29533 1 OPTION

7. Thyristor Unit for Control SKKT106L5Z2WHDK 1 Water cooling type

8. Heat Exchanger 1

9. Diffuser D4CX32625 1 Material : Ni

3-2 Clean Unit

1. Clean Module Unit BV-R15TU1G7N 1 Wafer transfer area (Z axis side)

2. Clean Module Unit FU37050KE 1 Rotation cassette Storage (Upper)

3. Clean Module Unit FU37096KE 1 Rotation cassette Storage (Lower)

4. Chemical Filter CBM3-C-1099600CF068 1 for wafer transfer area

5. Chemical Filter F-6000-053-0001 1 Intake for wafer transfer area

3-3 Controllers

1. Main / Operation Controller CX3010 1

2. Operation Controller CX3002P 1 ※1

3. DDC Temperature Controller CQ1700 1

4. MFC / Pressure Controller CX3202 1

5. Gate Drive Unit DN-150V-T5 1

6. Mechanism Controller Unit Robo5000 1

7. Valve / Interlock Control Unit CS1 1 Made By OMRON

8. Signal Tower (Front) WEP-402-RCGB 1 Red, White, Green, Blue

9. Signal Tower (Rear) MES-402A-RCGB 1 Red, White, Green, Blue

10. Relay chassis ----- 1

11. Gas Pattern Panel D4EX31991 2 Front, Rear

12. LON Adapter Control Unit CX2403 3 For CQ1700, Robo5000, AUX I/O

13. Uninterruptible power supply DBK05D-01A 1 For CX3010 Hard Disc

3-4 Drive Mechanisms

1. I/O Shutter ----- 1

2. AGV/PGV Stage ----- 1

3. FOUP Loader ----- 1

4. Rotation FOUP Storage ----- 1 FOUP receipt number : 16

5. FOUP Opener ----- 1

6. Wafer Detection ----- 1 25 in one lot.

7. Wafer Transfer ----- 1 Lift Transfer

8. Variable Pitch Wafer Converter ----- 1

9. Boat Elevator ----- 1

10. Boat Rotation ----- 1 OPTION

11. Notch Aligner ----- 1 OPTION

3-5 Quartz ware

Tweezer D2CN95780 5

3-6 Gas System

1. Gas Unit ----- 1 N2, SiH4, 1%PH3/Ar 1%O2/Ar, ClF3 Made by Fujikin

2. Mass Flow Controller SEC-Z500 series 1 Made by STEC

3-7 Exhaust System

?. Dry Pump/Booster Pump IH1800SC (BOC EDWARDS)

1 Supplied by Customer

2. Diaphragm Sensor (1000 Torr) 623A13TBE 1 Made by MKS

3. Diaphragm Sensor (10 Torr) 626A11TBE 1 Made by MKS

4. Differential Diaphragm Sensor (100 Torr) 223BD-00100 1 Made by MKS

5. Pirani Sensor PSG050 (Sensor) 1 Made by INFICON PSG051 (Sensor) 2 Made

by INFICON VGC-012 (Controller) 2 Made by INFICON

6. APC Valve VEC-S8-X0301 1 Made by CKD

7. APC Controller VEC-CA8-X0301 1 Made by CKD

8. Exhaust Piping ----- 1

9. Exhaust Dilution Line ----- 1

10. Reactor Tube Press Leak Line ----- 1

11. ATM Sensor PA830-102G-VCR 2 Made by Copal

12. ATM Gauge PZ200 2 Made by Copal

13. ATM Sensor (Double O-ring) PA830-102V-VCR 1 Made by Copal

14. ATM Gauge (Double O-ring) PZ200 1 Made by Copal

3-8 Load Lock Chamber

1. Furnace port ----- 1

2. Load Lock Chamber ----- 1

3. Gas Inlet ----- 1

4. Door Valve ----- 1

5. Furnace Port Gate Valve ----- 1

6. Gas Control For N2 Purge ----- 1

7. Exhaust Piping ----- 1

3-9 Special specification

3-9-1 Safety

1. Water leak detector (Detector) K7L-AT50 2 Made by OMRON

2. Water leak detector (Sensor) F03-16PE 3 Made by OMRON

3. O2 Detector DTF-201 1 Made by Enegy Support

4. Smoke Detector (Reception) CPC-2 1 Made by Nittan

5. Smoke Detector OIB 2 Made by Nittan

6. Light Curtain System SL-C32H 1 Made by KEYENCE SL-C20H 1 Made by

KEYENCE

3-9-2 Furnace

1. Bar Code Reader (Sensor) BL-601HASO(7099) 2 Made by KEYENCE

2. Bar Code Reader (Power) BL-U2 2 Made by KEYENCE

3-9-3 Other

1. Pressure Sensor E8Y-AR2Y-5 5 Made by OMRON

2. Gas Pressure Sensor HYPSMV-ND420 (MPA) 6 Made by TEMTECH

3. Cooling Water Flux Meter KSL-5L-24V 5 Made by REGAL JOINT

4. Cooling Water Flux Meter KSL-30L-24V 1 Made by REGAL JOINT

5. Cooling Water Pressure Gauge PA-858-103G-R2 1 Made by COPAL

6. Cooling Water Flow Meater DFM2-1000 1 Made by PURERON JAPAN

7. Cooling Water Flow Switch DFS3-2000 1 Made by PURERON JAPAN

4. SPECIFICATIONS

4-1 Resistance Heating Cartridge Heater

1) Number of control zone : 5 zones

2) Effective heater inner diameter :φ470mm

3) Heater element diameter : t1mm approx

4) Heater element material : KANTHAL APM

5) Heater length : 1445.5mm

6) Maximum heating temperature range : 1050℃ (in Furnace)

7) Flat zone length : 800mm (±2.5℃ at 400℃)

8) Maximum Power Consumption :≦90kW

9) Power consumption in stable condition :≦10kW (at 600℃)

4-2 Clean Unit

1) Dust collection ratio : ≧99.9999% (> 0.1μm)

2) Filter Materials : PTFE

3) Check method : Anhydrous silica method

4-3 Controllers

5-3-1 Main / Operation Controller (CX3010)

(1) Main Control

(a) Hardware

- CPU : PentiumⅢ (850MHz)

- Memory : 256Mbyte DRAM ,160kbyte ROM BIOS

- HDD : 20G byte (2.5 inch), RAID1 (Mirror Disk)

- FDD : 3.5 inch (1.44Mbyte / 720kbyte)

(b) Software

? Recipe

- Process recipe : 100 Files, 100 steps/recipe

- System recipe : 100 Files, 20 steps/recipe, 20 recipes/File

- Process parameter : 20

? Interlock

- Alert function : Temperature, Pressure, Gas flow setting can be Hi /

Low (Buzzer Processing)

- Alarm function : Temperature, Pressure, Gas flow setting can be Hi /

Low (Alarm Table Processing)

? Error Information

- Product information : 200 Record / File Manual backup : 10 Files/HDD

- Alarm information : 200 Record / File Auto backup : 500 Files/HDD (Only

20G byte Type)

- Maintenance information : 10 types

- Main Alarm ingormation : 200 Record / File Auto backup : 500 Files/HDD

(Only 20G byte Type)

- Trace logging : Temperature, Gas flow, Pressure

For each 1500 points graph and numeric data

(2) Main operation

- Display : 10.4 inch TFT color LCD, 256 Colors

- Resolution : 640×480 dot

- Operation key : Touch panel

- Back light control : Auto back light off

4-3-2 Temperature Controller (CQ1700)

(1) Temperature Control

- Temperature setting range : 200~1200℃

- Temperature detection : R type thermocouples

- Setting resolution : 0.1℃

- Control accuracy : ≦±0.5℃ (at 400~1200℃)

: ≦±1.0℃ (at 200~400℃)

- Output : Pulse output for Thyristor gate control

- Output control : Power proportional phase control

- Input for control : 5 points

- Calibration Input : 5 points

- Control period : 0.5 sec/loop

- Control mode : Programmable P.I.D.

P (proportional) : 0.1~200%

I (Integral) : 0.01~100.00 min

D (Differential) : 0.00~10.00 min

- Zero point Compensation : IC Temperature Sensor

(2) Over Temperature Protect

- Input for Control : 5 points

- Control Period : 0.5 sec/loop

- Temperature detection : R Type thermocouples

- Temperature Setting Range : 400~1350℃

4-3-3 MFC / Pressure Controller (CX3202)

(1) MFC Control

- Object of control : Mass Flow Controller

- Control Mode : Direct control, Ramping control, Soft start control

- No. of channel : Max. 16Ch.

- Input range for full scale : 0~99.999SLM

- Input range : 0~F.S.

- Resolution : 1/32768 F.S.R.

- Control accuracy :±2 % of full scale

- Control range : 2~100 % of full scale

- Ramping rate : 0.001~99.999SLM

- Soft start setting : Max. 16 pattern

- Soft start time : 0~99 sec.

- Error detectable deviation flow : 0~99 sec. (1 point per channel)

- Error detectable time : 0~255 sec.

(2) Pressure Control

- Controlled object : Conductance valve for Pressure control

- Input : Diaphragm Sensor

- Accuracy : ±5.0% of Set Point (at approx.50Pa)

4-3-4 Valve / Interlock Control (CS1)

(1) Valve Control

- Object of control : Solenoid valve

- Output voltage : DC 24V

- No. of channel : Max. 64Ch. (Max. 56ch when hard gas pattern panel is

used)

(2) Interlock Control

- No. of channel : Max. 64Ch.

Tool Damage/Missing Parts:

Please inspect tool to reconfirm

Dry pumps not included

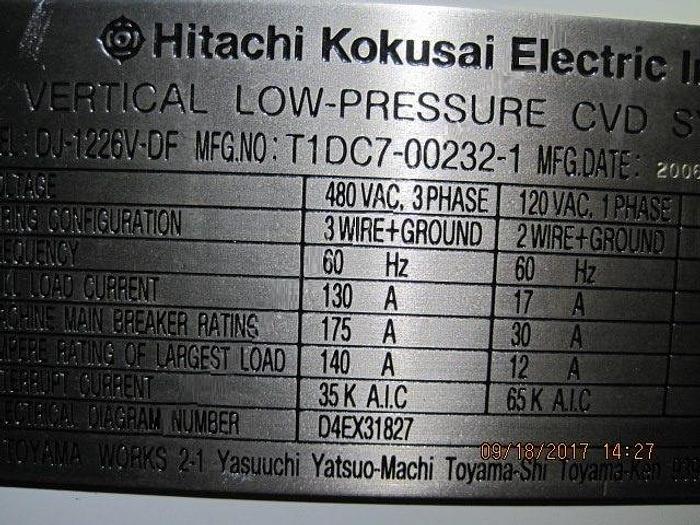

Specifications

| Manufacturer | Kokusai Electric Co., Ltd |

| Model | Quixace II Doped Poly |

| Year | 2006 |

| Condition | Used |

| Stock Number | BM575 |