2000 TEL ACT 8

2000 TEL ACT 8

Contact us for price

Description

Main Controller Type: TEL Controller #2

Wafer Flow: Right to Left

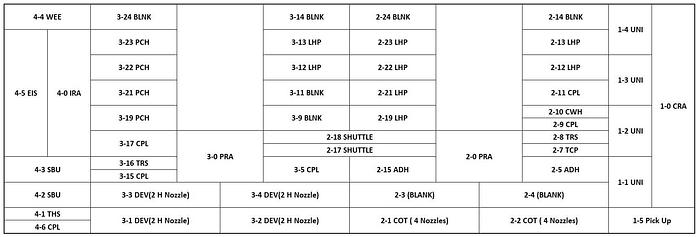

Configuration

A. Wafer Size: 200mm, DUV Application, Double Block System

B. Wafer Flow: Right to Left(CSB Unit is in Right side and Interface Station Unit is in Left side)

C. Process Block: 2ea(Double Block System)

D. Block#1

a. TEL Clean Track ACT8 EC/Equipment Controller#2

b. Stage/Index: CSB/Cassette Stage Block with 4 Stage

c. CRA/Cassette Block Robotics Arm: 1ea

E. Block#2

a. Coater Unit: 2ea(2ea of Normal Resist Unit at 2-1 and 2-2)

- 4 Resist Dispense Nozzle per Each Normal Resist Coat Unit(2-1 and 2-2)

- Each per units 1 Bottle 1 Nozzles(2-1 and 2-2)

- 1 Solvent Prewet RRC/Reduced Resist Coater Nozzle per Each Coater Unit

- 1 Side Rinse Nozzle(Programmable Side Rinse EBR) per Each Coater Unit

- Dual Back Rinse Nozzle per Each Coater Unit

- Resist Pumps of RRC Pump: 8ea

- PTI Exhaust Controller: 2ea

b. PRA/Process Block Robotic Arm: 1ea

c. ADH/Adhesion Process Station: 2ea

d. LHP/Low Temperature Hot Plate Station: 6ea

e. CPL/ Chilling Plate: 2ea

f. TCP/Transition Chil Plate: 1ea

g. TRS/Transition Stage Unit: 1ea

h. CWH/Cup Washer Holder Unit: 1ea

i. SHU/Shuttle Module: 2ea

F. Block#3

a. Develop Unit: 4ea

- 2 H Nozzle per Each Develop Unit(3-1,2,3,4)

Total 8 H Nozzles for 4 Develop Unit

- 1 Top Rinse Nozzle per Each Develop Unit

- Dual Back Rinse Nozzles per Each Develop Unit

b. PRA/Process Block Robotic Arm: 1ea

c. LHP/Low Temperature Hot Plate Station: 2ea

d. CPL/ Chilling Plate: 3ea

e. PCH/ Precision Hot Plate Process Station: 4ea

f. TRS/Transition Stage Unit: 1ea

G. Block#4

a. IFB/Interface Block: 1ea(Standard Interface Block)

b. IRA/Interface Robotics Arm: 1ea

c. Interface for ASML TWINSCAN 1250

d. WEE/Wafer Edge Exposure Process Station: 1ea

e. CPL/ Chilling Plate: 1ea

f. THS/Temporary Holding Stage: 1ea

g. SBU/Stationary Buffer Unit: 1ea

h. EIS/Interface Stage Module: 1ea

H. THC/Temperature and Humidity Controller: 1ea

I. External Chemical Cabinet#1

a. Solvent Supply System(with ejector system, no need Degas module)

- CSSS to Auto Supply System with Two of Buffer Tanks

b HMDS Supply System

- Auto Supply System with Two of Buffer Tanks

c. Develop Solution Supply System

- CSSS to Auto Supply System with Two of Buffer Tanks

- Degas Module: need, 1ea, 520cc

d. Resist Bottle System

- Resist Bottle: 8 Bottles

- Photo Resist Auto Exchange: N/A

- L/E tank & L/E sensor: yes

- Type of bottles: 1 Gallon glass type

J. TEL OEM TCU/Temperature Control Unit: 1ea

- SMC Circulator Pumps and Thermo Controller

K. Power Transformer AC Cabinet: 208VAC, 3 Phases, 50/60Hz

L. Software Options

a. Software Version: 2.04.000

b. On-Line Software(TEL GEM Standard)

c. Software Option

- Parallel Processing Software

- Process Log Software

- Advance Cascading Software

3) Wafer Details

A. Wafer Size: 8, Flat & Notch Type

B. Wafer Material: Si

4) Detailed Specification

A. Block#1: CSB/Cassette Station Block

a. TEL Clean Track ACT8 Controller#2

b. Stage: Cassette Stage Block 4 Stage

c. CRA/Cassette Block Robotics Arm 1ea

B. Block#2: Coater Units

2ea(2ea of Normal Resist Unit at 2-1 and 2-2, 2ea)

a. Dispense Nozzle Quantity: 4ea per Nozzle Resist Coater Unit

Total 8ea Resist Nozzles for 2 Coater Units

b. Pump Type: RRC Pumps

c. Coater Cup Temperature Synchronized Control System and this is controlled by 2-1

d. Photo Resist Temperature Control: Installed

e. Motor Flange Temperature Control: Installed

f. Photo Resist Drain Type: Direct Gravity Drain Type

g. Side Rinse: Programmable Side Rinse EBR per Each Coater Unit

h. BACK Rinse: Dual Type per Each Coater Unit

i. 1 Solvent Pre-wet RRC/Reduced Resist Coat Nozzle per Each Coat Unit

j. Photo Resist Bottle Quantity: 8ea for 2 Coat Unit External Photo Resist Supply

k. Photo Resist Auto Exchange: N/A

l. Auto Dummy Dispense System: Installed

m. Cup Type: PP for Upper Cup and Inner Cup

n. PRA/Process Block Robotics Arm: 1ea

C. Block#3: Develop Units

a. Dispense Nozzle Quantity: 2ea per Each Develop Unit and Total 8ea for 4 Develop Units

b. Dispense Nozzle Type: H Nozzle

c. Develop Temperature Control: Installed

d. Motor Flange Temperature Control: Installed

e. Drain Type: Direct Gravity Drain Type

f. Top Rinse Nozzle: Installed(1 Nozzle) per Each Develop Unit

g. Back Rinse Nozzle: Installed(Dual Types) per Each Develop Unit

h. Auto Damper: Installed

i. Auto Dummy Dispense System: Installed

j. Cup Type: Cup and PP for Inner Cup

5) Chemical Supply System

A. External Solvent and Develop Solution Chemical Supply System

a. 1st Section: Solvent Supply System for 2 Coat Units

- Solvent Chemical Type: 1ea

- CSSS to Auto Supply System with Two Buffer Tanks

- Tank Type: 2 Buffer Tanks(3 Lite/Tank Teflon) to Cover 2 Coat Units

- Tank Auto Switch -off/ Exchange: Installed

b. 2nd Section: HMDS Supply System

- HMDS Chemical Type: 1ea

- TEL OEM Standard N2 Bubbling Buffer Type

- Tank Type: 2Buffer Tanks(3 Liter/Tank, Teflon) for 1 Type of HMDS for 1 ADH Units

- Filter: Yes, 1ea

c. 3rd Section: Develop Solution Supply System for 4 Develop Units

- Develop Solution Chemical Type: 1ea

- CCSS/Central Chemical Supply System to Auto Supply System with 2ea of 3 Liter

Buffer Tanks

- Tank Type: 2 Buffer Tanks

- Tank Auto Switch -off/ Exchange: Installed

- Degas Module: 1ea(520cc)

d. Chemical Supply System Cabinet for 60Liter Canister

- Developer, Solvent Only

- HMDS Canister Re-check

B. External Photo Resist Supply System

a. Photo Resist Supply System

- Resist Bottle: 8 Bottles

- Photo Resist Auto Exchange: N/A

- L/E tank & L/E sensor: yes

- Type of bottles: 1 Gallon glass type

6) Accessories

A. TEL OEM AC Power Transformer Unit: 1ea

B. TEL OEM Komatz THC: 1ea

C. TEL OEM SMC TCU: 1ea

D. Chemical Cabinet: 1ea

a) Chemical Supply Cabinet #1 (60 Liter Canister)

b) Chemical Cabinet(In the 5 Liter Buffer Tank)

c) Resist Supply Cabinet

Specifications

| Manufacturer | TEL |

| Model | ACT 8 |

| Year | 2000 |

| Condition | Used |

| Stock Number | BM2218 |