2011 Applied Materials Producer eXT

2011 Applied Materials Producer eXT

Contact us for price

Available quantity:2

Description

Process: poly etch

Wafer size: 300mm

Carrier: FOUP (Comply with SEMI E47.1 (25wafers))

Load Port: 3 Loadport

Facility Plate: N2 Regulator :CDA regulator 125 PSI onboard SMC pressure switch

Anti-corrosion Package: Enhanced Corrosion abatement material for FI

Anti-corrosion Package: Side Storage Pods (Left)

Anti-corrosion Package: Exhaust Mid Deck and Plenum for FI

Anti-corrosion Package: Heated SWLL

Loader Mod Corrosion Preventio: TDK Corrosion Resistant

Fittings: No brass fittings

Loadlock Pressure Monitor: GAUGE CONVECTRON 1MTORR-1000TORR 1/4FVCR DNET, 3310-01187

Transfer Pressure monitor: GAUGE CONVECTRON 1MTORR-1000TORR 1/4FVCR DNET, 3310-01187

Transfer Pressure monitor: 5 SLM N2 MFC, software regulated, 3030-14249

Signal Tower: KIT, 4 LIGHT, DNET CONFIGURABLE LIGHT TOWER, 5.3 F

EMO: Front x3, Rear x3

Cable Length: RF SOURCE CABLE TRU-9957-07, RF BIAS CABLE TRU-9958-21

Cable Length: Monitor 1/2 cables : 25 ft (16 ft effective, AMAT#0395-00104)

Cable Length: Pump Cable : 75 ft

Monitor: Monitor-1 : Flat Panel with Keyboard on Stand (AMAT#395-00099)

Monitor: Monitor-2 : Flat Panel with Keyboard on Stand (AMAT#0395-00099)

IPUP: Alcatel IPUP , P/N 0190-22363

Inter Locks: On board interlocks to dissable RF and gas flow at half atmosphere,

lid or gas panel door open, and H2 over press.

Inter Locks: On board interlocks to disable robots and slit doors when transfer lid or load lock lids are open.

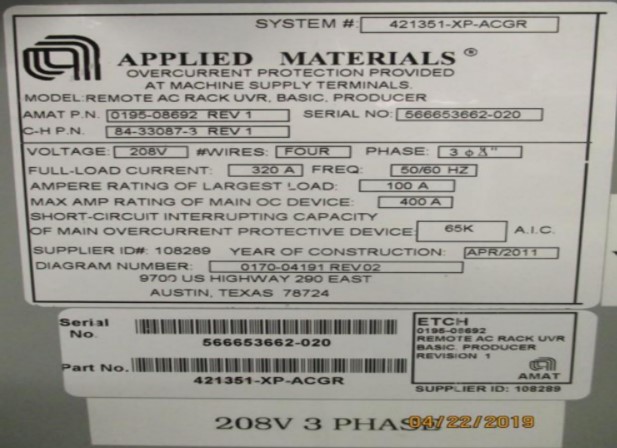

Etch Common AC Rack: Lean AC Rack

Heat Exchanger WALL: H2000 Heat Exchanger Wall

Heat Exchanger CATHODE: SMC 496 Heat Exchanger Cath (new DI -solenoid valve with new tolerance)

HX Control Cable Length: 75 Feet

Heat Exchanger Hose Length: 75 Feet

Water Box: Water Box

Source RF Generator: Apex 2760 2.7KW 60 Mhz

Source RF Matcher: RF MATCH, 60 MHZ, 5 KV, 50A AE NAVIGATOR 2060, PRODUCER ETCH SOURCE

Bias RF Generator: Apex 5513 5.5Kw 13.5Mhz

Bias RF Matcher: RF MATCH, 13.56 MHZ, 4 KV, 50A AE NAVIGATOR 5513, PRODUCER ETCH BIAS

ESC high Voltage Power Supply: CT HV MODULE ASSY. 5KV, CESC

Factory Interface Robot: Kawasaki KA3 single fixed robot

Mainframe Robot: VxP w/DP blade and 3 Pt orings

OCR: KA3 backside OCR kit

OCR: KA3 backside Camera

Orienter: Prealigner kit

Orienter: Prealigner

Soft chuck: Soft chuck on pre-aligner

Process Chb.1,2,&3: Producer eXT Poly Process Kit

Electrode: Y2O3 GDP Dual Zone

He Control: Single Zone

Cathode Outer Cover: None

Cathode Sleeve: KIT, Cathose Sleeve Y2O3 (full coat)

ESC: Small OD ESC

Endpoint type: H.O.T. Pack

Slit Valve Liner Door: KIT, Slit Cover Door with Y2O3, Producer Etch XT

Oring for Slit Valve: 8575 Kalrez

CCM: 400mHz CCM

Hoop Assy: New Hoop Assy

Lift Pins: New Lift Pins

Turbo screens: Removable Turbo Screens

Slit Valve: Reduced Pressure sv

He Dump Kit: He Dump Kit

Chamber Divider: Installed

TMP: KIT SEKIO SEIKI Pump and installation

Pump Cable Length: 75 Pump Interface Cable

Dry Pump Interface: Pump Interface Cable

Dry Pump Breaker Amp: 40A

Gas Break: Spiral 0040-54702 (electrode assy)

Gas Break O-ring: Gas Break O-ring

Pressure Monitor: Service : SXDCRPRESS 100TORR 1/2FVCR 0-10V OUT 0.5%ACC 9P-D

Pressure Monitor: Process Chamber : XDCR PRESS 1TORR 1/2FVCR 15P-D 45DEG-C MANOMETER

Pressure Monitor: ATMOSPHERE SWITCH: MKS 760 torr switch

Pressure Monitor: 1/2 ATMOSPHERE SWITCH: MKS 75 torr switch

Pressure Monitor: FORELINE : Manometer

Gas line 1: Gas line 1-Toxic-HBR 200 sccm- Celerity UNIT 125-SC23

Gas line 2: Gas line 2-Toxic-NF3 500 sccm- Celerity UNIT 125-SC25

Gas line 3: Gas line 3-Toxic-CL2 250 sccm- Clelerity UNIT 125-SC24

Gas line 4: Gas line 4-Toxic-CH2F2 100 sccm-Celerity UNIT 125-SC23

Gas line 5: Gas line 5-Toxic-O2 200 sccm-Celerity UNIT 125-SC23

Gas line 6: Gas line 6-Toxic-O2 2000 sccm-Celerity UNIT 125-SC25

Gas line 7: Gas line 7-CF4 700 sccm-Celerity UNIT 125-SC25

Gas line 8: Gas line 8-CF4 100 sccm-Celerity UNIT 125-SC22

Gas line 9: Gas line 9-N2 200 sccm-Celerity UNIT 125-SC23

Gas line 10: Gal line 10-Ar 100 sccm-Celerity UNIT 125-SC22

Gas line 11: Gas line 11-CHF3 200 sccm-Celerity UNIT 125-SC24

Gas line 12: Gas line 12-Ar 1000 sccm-Celerity UNIT 125-SC24

Gas Pallet: ASSY, FULL 6/6 PALLET, 300MM ETCH NEXT GEN

Regulators: Regulator on SLD for inlet to gas panel (1 per unique gas, 12 max, VCR connection)

Transducers: Transducers inside MFCs

Device Net MFCs: Unit 125 Multiflo PTI

Filters: MYKROLIS (nickel, VCR)

Filters: Nippon (VCR 12 max)

FRC Location: at Gas Panel (setting = 1000/1000)

Gas Panel Exhaust: TOP EXHAUST

Gas Panel Facilities Hook Up: SINGLE LINE DROP

Piping: Standard high purity stainless & Exhaust through Gas box)

H2 Gas Leak Detection Port: H2 Gas leak detect board circutry supplied for use with external(with interface to customer-supplied toxic gas leak detectors)

Final Pressure Switch: At 600 Torr from gas pallet, at chambers 75 torr

Specifications

| Manufacturer | Applied Materials |

| Model | Producer eXT |

| Year | 2011 |

| Condition | Used |

| Stock Number | BM1177 |